Fire Hydrant service & inspection throughout Bedfordshire, Milton Keynes & the surrounding areas.

Fire hydrants are located in public spaces and on private properties. Hydrants on private property are the responsibility of the owner or occupier of the site.

Fire Hydrant locations are found by hydrant marker posts and indicator plates. The plates top number shows the water main size in mm feeding the hydrant, the bottom number indicates the distance in metres from the plate to the hydrant.

British Standard BS9990:2015 states that where a fire hydrant exists on your premises, arrangements should be made by the owners or occupiers for annual maintenance.

TEC Fire & Security can carryout the test and inspection of hydrants on your site throughout Milton Keynes, Bedford and the surrounding areas.

A typical Hydrant test and inspection will include

the information shown is correct and is clearly visible, any obstructions or overgrowth removed.

A Below ground inspection will Involve checking the hydrant pit and the hydrant.

The hydrant is checked for leaks.

The water pressure and flow are checked and recorded.

The hydrant pit is cleared of debris.

Any remedial works or non-conformities will be advised as to inform the responsible person of further actions required.

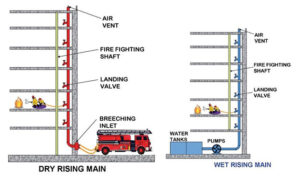

‘Dry Risers are vital for fire fighting in tall buildings, their correct maintenance is therefore essential. Approved Document B (Fire Safety) of the Building Regulations requires that any building more than 18m high, measured from the fire brigade access level to the top floor requires a dry riser. Dry risers can be installed below this height if the there is no access at ground or inlet level for a fire appliance. Wet risers are required in buildings over 50 metres.

A dry rising main is a system often found but not limited to high-rise buildings. The system consists of pipe work running up through a building with landing valves located on each floor. The pipes in dry risers are empty and only filled with water from a fire engine connected to the dry riser inlet, by fire fighters on their arrival at an incident. The fire appliance pump ensures the correct flow and pressure of water is supplied to the floor of the fire. The fire engine water supply is taken from the nearest fire hydrant.

Fire Fighters can then connect hoses to landing valves, which are then opened to allow the water in the dry rising mains to charge the hoses, enabling the fire to be fought. This system takes away the need for fire fighters to take hoses up and through a building which wastes valuable time and would cause an evacuation hazard.

In wet risers the pipes are always full of water and have pumps that deliver the water to the outlets, these pumps draw water from storage tanks. The pumps operate when the pressure in the mains drops when a landing valve is opened. Wet risers are required in buildings over 50 meters BS9990:2015 Code of Practice for Non-Automatic Firefighting Systems in Buildings recommends that wet and dry riders are serviced every six months. It is a legal requirement of the buildings responsible person to ensure this servicing is carried out. Service and maintenance should consist of one visual inspection every six months and 1 major service every year.

The visual inspection is vital to check for signs of wear and tear, missing parts and damage, that could affect the system working correctly when required to do so. The interim service is a check of all inlet and outlet valves, washers and gaskets, and a check to make sure they all open and close. The external cabinet is visually checked for signs of damage and corrosion and we ensure all signage is visible and correct to the latest standard.

Dry risers need to be pressure tested once a year up to 10 bar for a minimum of 15 minutes, this is the only effective way of testing the equipment. The breeching connector at Ground Floor or at Fire Service Access Level, along with Landing Valves and outlets are checked for leaks or faults.